3

DEVELOPMENT

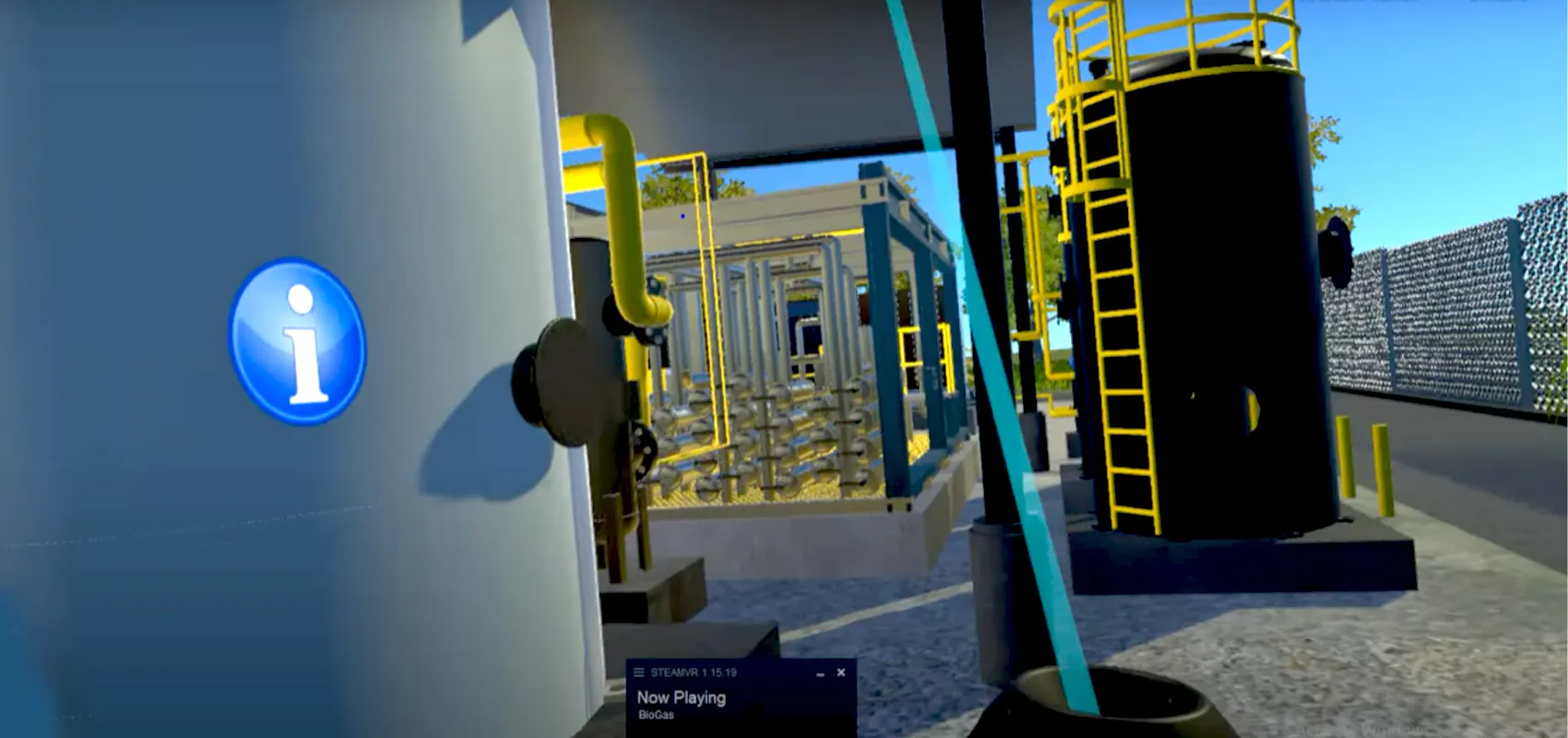

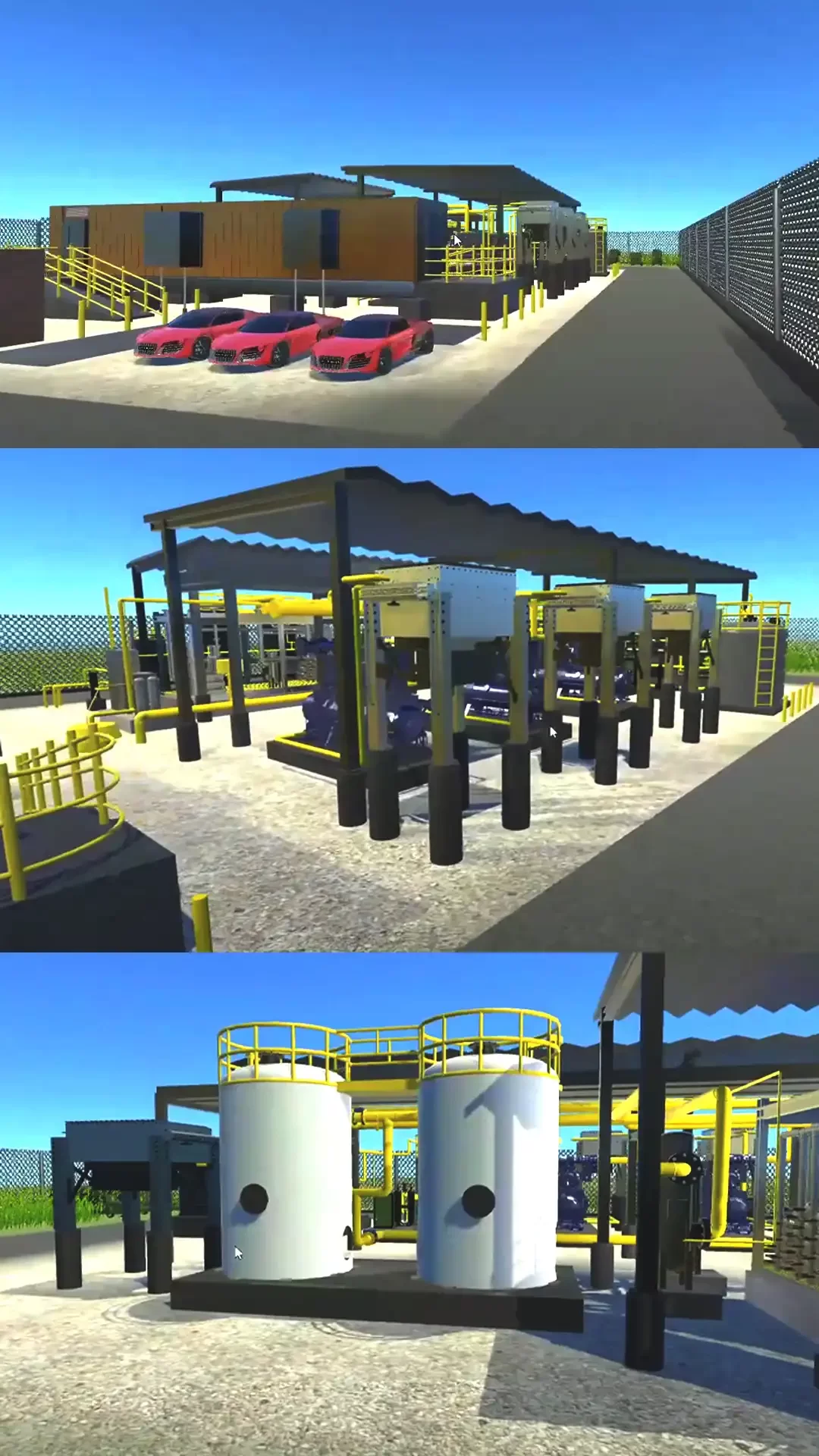

- 3D Models of Machinery

- Ray Casting for interaction

- Physics Integration for realism

- Digital Twin Development

Biogas Engineering Inc is a US-based international engineering, procurement, and construction company that set up turnkey biogas plants for their clients. They found the existing ways of displaying plant architecture such as 2D blueprints, CAD-based isolated 3D models, etc restrictive.

The advancements in immersive technologies like VR prompted them to use it for impactful plant visualization for their prospective clients. This is where Queppelin’s expertise in the domain came in handy. Our discussions zeroed in on VR-based Digital Twin development of their Biogas plant.

We developed a hyper-realistic audio-visual digital twin of the client’s Biogas Plant with high interactivity. Not only visitors can interact and operate machinery such as motor pumps, digesters, mixing tanks, etc. but also observe the actual sound in that environment.

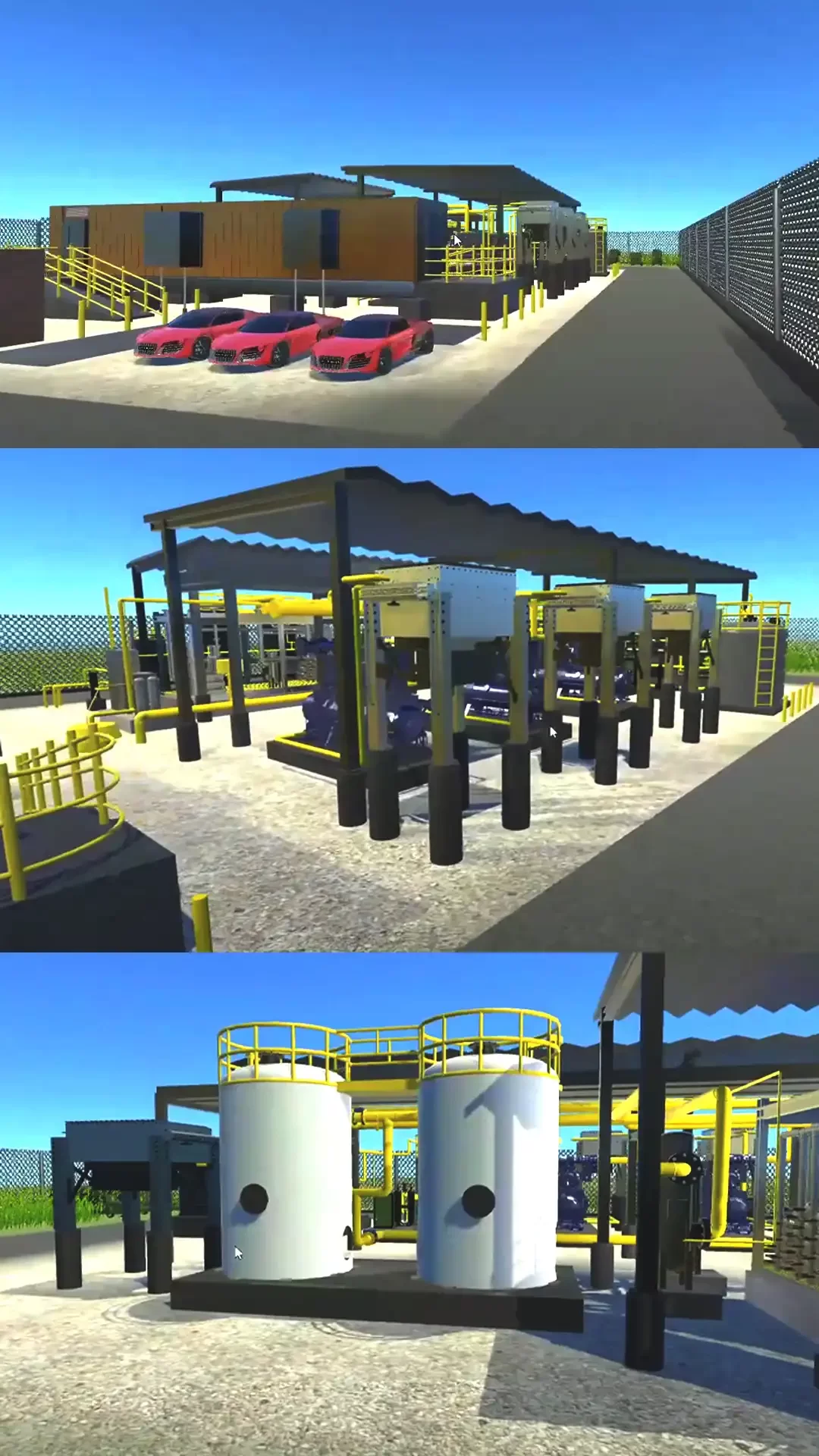

Prospects can enter the VR-based Biogas plant to get an idea of the architecture, the operational methodology, the types of machinery, the capacity, etc. We also included multiple chambers in the facility for different processes mirroring the actual workflow in the plant.

Our clients used 3D plant models for multiple objectives like product visualization, virtual plant tour, and VR employee training.

A major challenge was to identically replicate the live site in terms of both appearance and functionality. With the help of intense data gathering, we understood each piece of machinery and replicated its physical build, functions, gas flow, and workflow of the whole plant. More importantly, all of these were made interactive just like in the real world.

Creating a Digital Twin required intense data gathering of the real-world site. We gathered data on equipment dimensions, operational efficiency, plant productivity, etc. to construct virtual models, cyber-physical connections, and intelligent operations.

Although our client had CAD models of their machinery they were not compatible with the VR technology. Hence, we had to build each and every 3D model from scratch. Our team tirelessly worked to develop realistic 3D models of hundreds of small and large pieces of machinery.

Our clients demanded realistic 3D models to impress their own prospects. They wanted to offer realistic plant visualization for an impactful business proposal and our development team deftly executed the task. We developed these 3D models with realistic texturing that matched exactly with their real-world counterparts.

The project involved hundreds of 3D models functioning in tandem like an actual real-world plant. We ran intensive testing to spot lacunae, develop solutions, and evolve the plant with time for flawless execution.

The way we replicated the biogas plant to the inch-perfect detail, impressed our client. Not just the construct we also matched the functionality. The virtual plant had the same equipment, arrangements, and workflow.

Our client showcased their VR plant to their prospect and at trade fairs to raise brand awareness, build a wide business network and establish a strong market presence.

increase in the number of projects bagged.

increase in qualified sales opportunities in the pipeline.

VR Trainings assisted the client in achieving a fourfold increase in emotional connection and retention.

Queppelin’s decade-spanning expertise gets you a virtual asset in the form of the VR Digital Twin. It helps your showcase your capability in the best light and contributes to your networking and brand-building endeavors. We also add training capability in the VR Experience for you to offer experiential and scenario-based training to your employees. This exponentially improves their knowledge and expertise and contributes a great deal to your business growth.